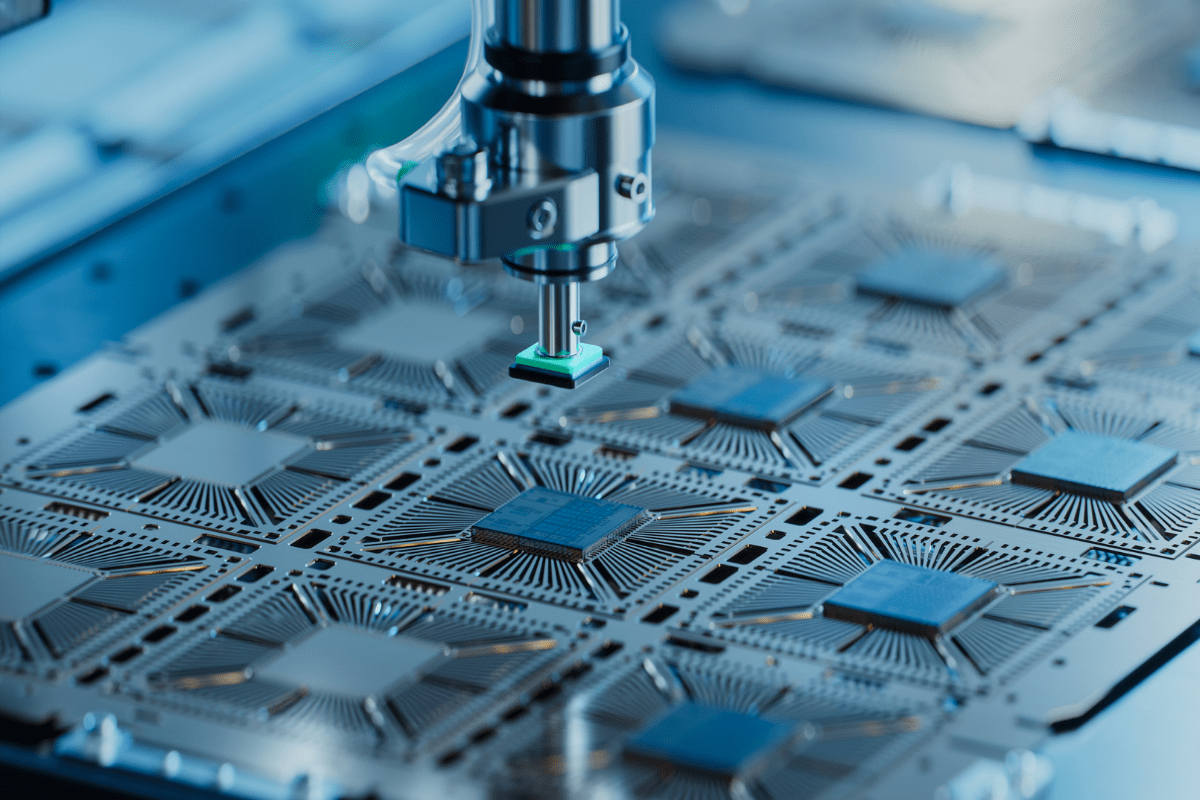

PCB semiconductor

“Cool and Precise, Technology Constant Temperature Source -- Professional Chiller Unit, Providing Stability for Precision Manufacturing”

“Cool and Precise, Technology Constant Temperature Source -- Professional Chiller Unit, Providing Stability for Precision Manufacturing”

Demand for high-precision temperature control

Noise and vibration

High water quality requirements

High reliability requirements

• Keep detailed records of all equipment cooling needs and environmental conditions.

• Calculation of refrigeration demand: According to the heat generation of the equipment on the production line, environmental conditions and other factors, the required refrigeration capacity is calculated accurately.

• Clear water quality requirements: Confirm the purity level of the cooling water required, which usually needs to meet ultrapure water standards.

• Type of unit: choose water-cooled or air-cooled chiller units according to geographical location and resource conditions.

• Consideration of environmental conditions: Evaluate the space of the installation site, noise control, cooling water source (air- or water-cooled), power supply, etc.

PCB and semiconductor manufacturing have extremely high requirements for temperature stability, so the chiller must have high-precision temperature control capabilities, usually requiring temperature fluctuations of less than ± 0.1 ℃.

• Pre-treatment system: Multi-stage filtration system (coarse filtration, fine filtration, RO reverse osmosis membrane, etc.) is installed to ensure the purity of cooling water.

• Circulation system design: adopts closed circulation system to reduce water consumption and maintenance cost, equipped with automatic water replenishment and drainage function. Intelligent and automated control.

• Integrated control system: the chiller should be integrated into the factory's automated management system to support remote monitoring, fault warning, automatic temperature adjustment and other functions.

• Internet of Things (IoT) technology: Utilizing IoT technology to achieve real-time data collection and analysis, and to improve system efficiency and response speed.

With strong technical force, excellent process equipment, perfect testing methods, the company takes the lead in applying the products in the field of industry and agriculture, and the series of products researched and developed are always in the leading level of the domestic cold and heating equipment manufacturing industry.